Services

We understand that even the best concrete has its imperfections in the form of cracks, discolouration, pop-outs, dirt and stains, or other issues.

While repairing concrete can help fix some of these issues, the repairs themselves can be noticeable and unattractive.

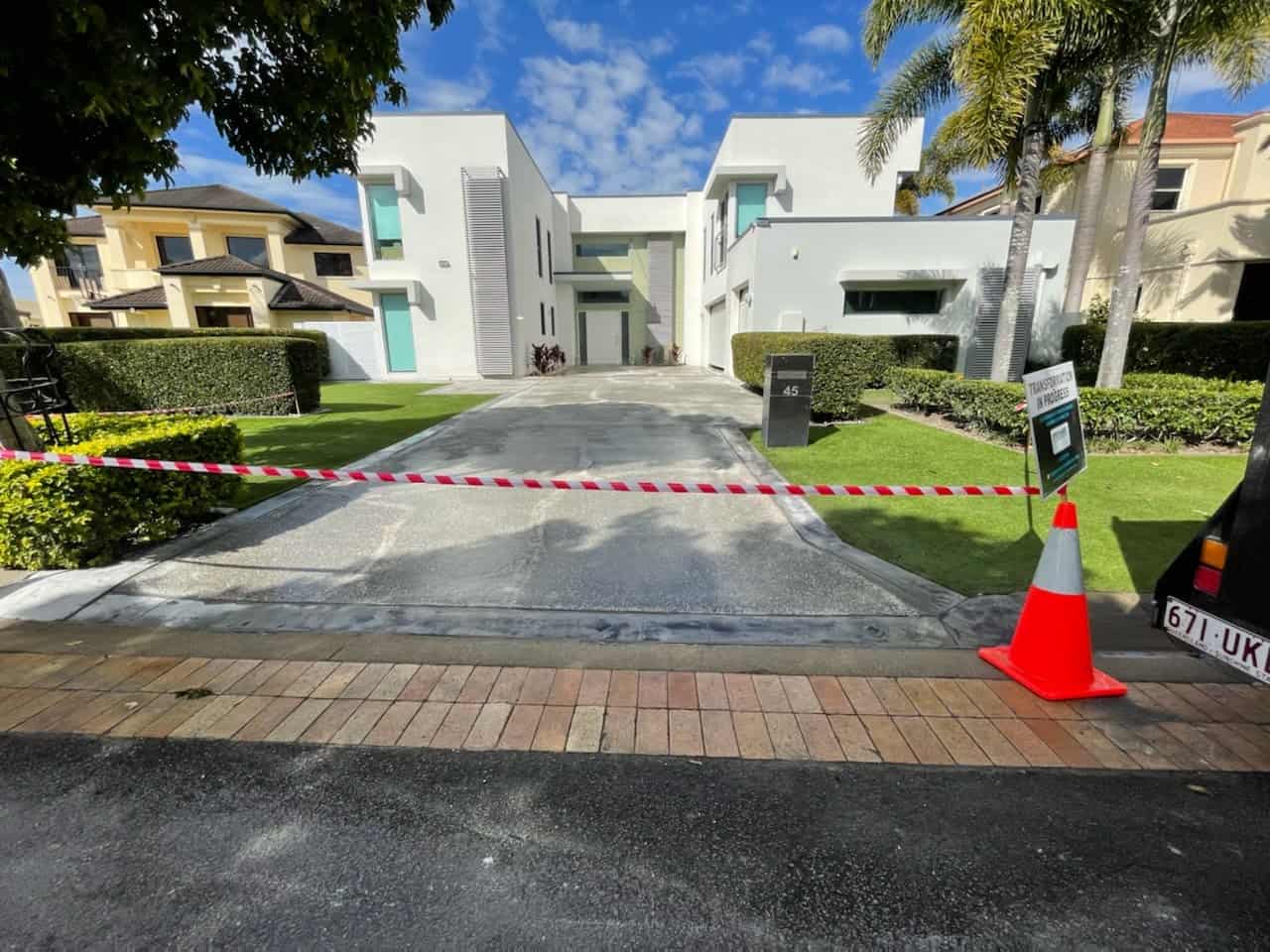

Many property owners think their only recourse for improving the look of unsightly old concrete is to rip out and replace their concrete. This we can do, but first, we need to determine if the concrete can be restored and a decorative concrete coating applied.

However, even if the concrete looks bad, the concrete may be in perfectly good condition, and therefore there are economical alternatives available.

Contact us to discuss your situation and what you want to achieve and we will offer you solutions to help you to solve the problem or produce the outcome you desire.

We can transform the surface with a complete face-lift with our concreting services, which could be a decorative concrete resurfacing solution, an epoxy coating, polished concrete or a new concrete solution. Plus, you’ll most likely save money, conserve resources, and minimise concrete disposal and replacement problems.

For external concrete, resurfacing your concrete with a decorative concrete coating or polishing your concrete is an economical and smart way to upgrade the look of your concrete areas. However, there are different solutions to consider.

For internal floors, popular coatings include epoxy, polyaspartic or urethane systems, however, a hone and seal of the concrete can give it a modern, industrial or retro look that can look great.

If your concrete is in good condition but could just be dirty or stained, you may think it needs a face-lift. There are many creative options to transform the appearance of your concrete, it’s like a canvas you can paint on – but we don’t recommend paint! A popular option is to hone and seal the concrete, apply an epoxy or urethane coating, or create a polished concrete floor.

If your concrete is older and outdoors, and there are ugly cracks and imperfections, a decorative concrete coating could be the solution.

If you want the maximum profit when you sell your property or are considering transforming the appearance of your property, please contact us so that a professional estimator can evaluate your requirements and advise you on the best solution for you.

- Concrete resurfacing

- Epoxy coatings

- Urethane coatings

- Concrete cleaning and sealing

- Honed finish floors

- Polished concrete

- Surface Preparation

- Removal of coatings

- Concreting

- Concrete maintenance

- Grinding and sealing

- Grinding and polishing

- Tile removal

- Same day sealing

Preparation

A company can claim to have the best products and systems, however, no matter what type of overlay work they do, or what type of concrete stencilling, the most critical factor contributing to long-term performance is adequate surface preparation.

As expert installers, we have discovered that the best process is thorough mechanical surface preparation. This is a change from 10-20 years ago when most installers would rely on acid etching, chemical cleaners and power washing to adequately prepare the surface.

Barefoot Concrete recommends mechanical surface preparation, this is the best option, however, due to a client’s budgetary constraints, we can still adequately prepare the surface by pressure cleaning and chemical cleaners, but there is a greater risk of delamination.

We have found that 90% of all concrete that needs to be prepared for an overlay requires a minimum concrete surface profile (CSP) of 3 (light shot blast), or 2 (grinding), as recommended by the International Concrete Repair Institute in order for the proper bonding of a concrete coating or overlay.

Barefoot Concrete not only recommends the use of the right equipment but to also to use a better system of primers and repair products. As part of Barefoot’s preparation process, we not only recommend mechanical surface preparation but also recommend the use of a densifier as a moisture blocker as best practice for adhesion and moisture control.

We know that a callback, for both the customer and the applicator, because of a system failure caused by moisture, is much worse than the upfront cost per square meter for a moisture-control solution as part of the overlay system.

Crack repair

Barefoot Concrete has also improved the way we deal with cracks and patching.

To minimise cracking the concrete needs expansion joints cut into the concrete at a minimum of every three meters to allow for the expansion and contraction of the concrete without it causing stress fractures.

The applicators can also no longer take a “hope for the best” approach with inadequate crack repair processes, as cracks will most likely reappear and visibly affect the concrete overlay.

Proper crack repair techniques are essential to minimise the chances of the crack reappearing.

Therefore, as part of the mechanical surface preparation process, we apply saw cuts, grind out the cracks, and fill them with a polyurethane or epoxy crack repair solution.

As part of the preparation to patch any pop-outs, divots or voids, we use a high-quality, rapid-setting, cement-based repair mortar and patching compound prior to priming the surface.

If the surface has an existing coating or sealer we use mechanical grinding, shot blasting, or sandblasting to remove the existing costing so that the new overlay bonds properly to the prepared surface.

When it comes to concrete cracks, we don’t recommend concrete paint as a solution to cover up cracks and imperfections. Concrete paint fades, peels, chips, bubbles, or delaminates – it inevitably fails and doesn’t last!

If you take the cheapest option, and especially if it’s concrete paint, please call us now for an alternative, we will save you the embarrassing cost and eyesore of a failed job.

Barefoot Concrete believes in doing it right the first time! As such we follow this basic rule: First, we figure out what caused the damage.

Second, we do the necessary preparation of removing any unsound concrete and contamination.

Third, we implement a durable solution designed to solve the problem.