Polished Concrete

Barefoot Concrete supplies honed finish floors and polished concrete services on the Gold Coast.

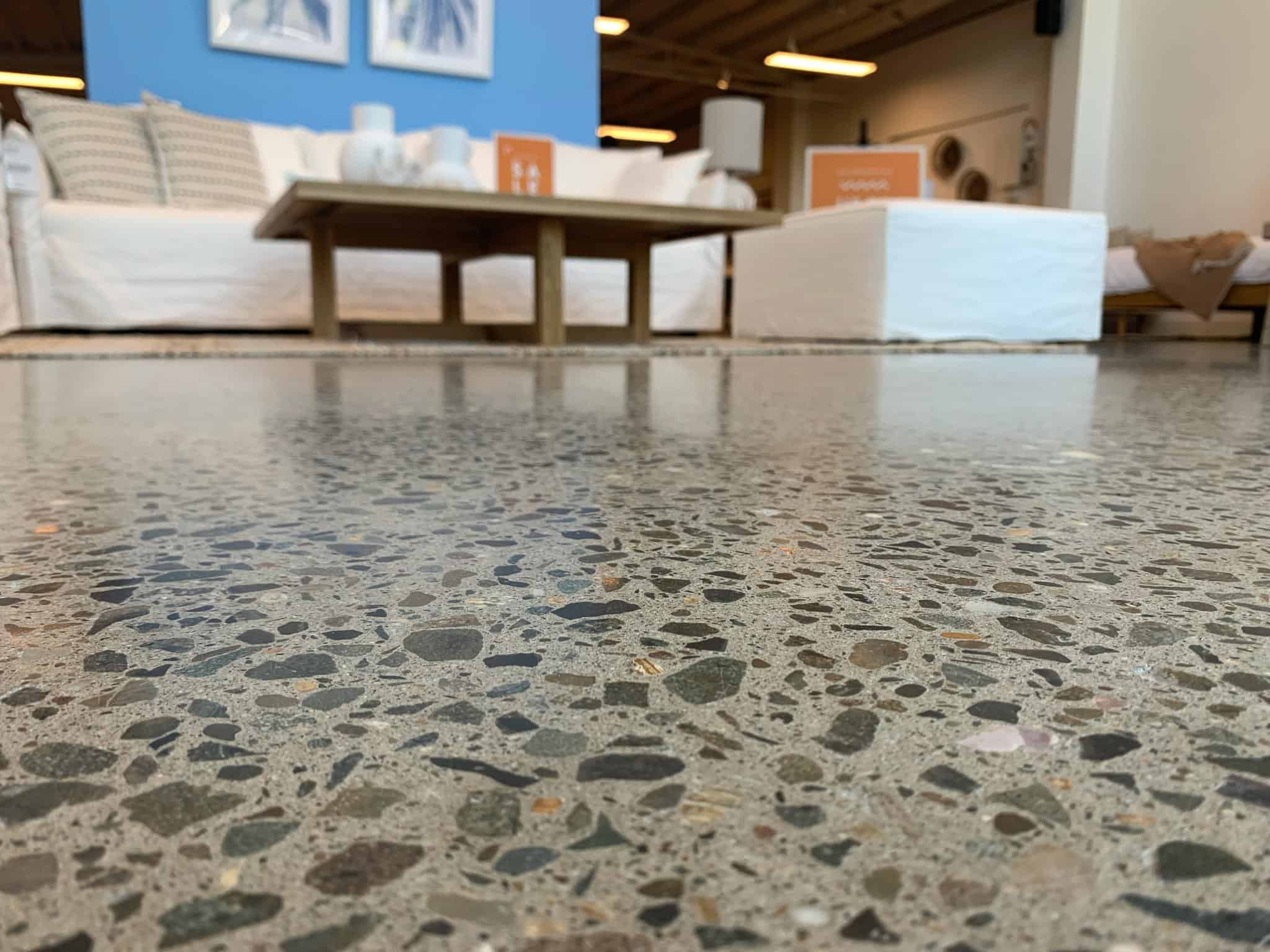

Polished concrete, and honed and sealed concrete, are becoming very popular for both internal and external concrete floors. It is a modern feature that is retro and stylish and on the agenda of those modernising their homes.

We would consider polished concrete as the ultimate flooring material. It’s tough, durable, attractive, and easy to maintain. When contractors combine the proper floor grinding equipment, products, techniques and experience, they can grind concrete surfaces, whether new or old and turn them into a modern and functional floor.

Factor in the superior durability and performance of concrete, and it’s why retail, industrial, commercial warehouses, modern office facilities, and even homeowners are catching on to the appeal of these smooth, high-lustre floors.

What are the benefits of polished concrete?

Residential Benefits

- Cost savings: Traditional floor covering materials are not necessary when the slab on grade is used as the finished floor surface

- Longer life-cycle savings: Polished floors are not as vulnerable to damage as other materials and do not need replacing

- Easy to clean: Won’t harbour dust, dirt, allergens

- Available in a wide variety of colours and designs

Commercial and Retail Benefits

- Cost savings: Using the slab on grade as the finished floor surface is more cost-effective and the maintenance costs are lower

- More resistant to high foot traffic: A business can maintain their traffic areas within a store at minimum cost, which saves time and money because they don’t have to move things around to wax and strip the floor

- Less maintenance and longer service life: Polished floors are easy to clean, requiring only occasional damp mopping. They also eliminate the need for messy waxes or coatings as well as the associated labour, time, and expense to apply them. Also resists staining from oil and chemical spills

- Resistant to moisture transmission issues: Polished concrete allows the floor to breathe and eliminates issues that arise with other flooring materials that seal off the concrete such as tiles

- High light reflectivity: Important for office building floors, hotels, restaurants, and other public facilities that want to project a bright, clean, professional image. Saves energy by reducing artificial lighting requirements

- Is a sustainable flooring alternative: Polished concrete does not require hazardous coatings, cleaners or adhesives

Honed Concrete Floors

We use a hone and seal process when customers want a polished floor look. This process of honing and sealing concrete produces an even and smooth matte finish depending on what kind of sealer is used.

A honed concrete floor offers a great flooring solution to your concrete in outdoor areas. The way we do it is to grind the desired exposure of aggregate and then apply a polyurethane sealer or a penetrating sealer. This will leave a hard-wearing non-slip finish to your outdoor concrete slab.

Honed concrete looks similar to polished concrete but without all the polished concrete steps and makes your concrete look fantastic, especially if it is an alfresco outdoor area, outdoor entertainment area or pool surrounds. The hone and seal service is more affordable than polished concrete and remains virtually maintenance-free for many years.

Contact Barefoot Concrete to discuss your polished concrete or hone and seal needs.

Polished concrete products

The products which we are able to offer, fall into the following categories:

- C-Complex for cutting and grinding concrete

- C-Complex for coating removal

- Grout polymer

- Potassium densifier

- Colloidal densifier

- Penetrating sealers

- Primers

- W881 Sealer

- B883 Sealer

- G887 Sealer

- Pretaped masking film

- Construction tapes